The Tube shape button allows to

edit the tube like an ordinary AoI tube. Usually, though, you would set

the thickness of the tube for individual points (or a selection of

them). The TaPD tube uses a customised function, exactly like the

spline mesh object. This function is defined using the R Shape button. Like for the spline

mesh object, the tube control points define the resolution of the Y

curve of the tube object. Any consideration discussed in the spline

mesh object section are valid for the tube object, except of course

those addressing cross-sections.

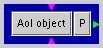

Set texture and Set material allow to assign texture

and material to the tube (the ends of which are flat).

The Deliver duplicate

and Hidden checkboxes works

the same way as for the AoI object module discussed

earlier.

Tube objects use much less memory (and rendering time) than spline mesh

objects. Hence, they should be preferred to spline mesh objects

whenever possible.

3.2

Geometry modules

All

geometry modules show a maroon background. They always have at least

one object input and one object output. There are two kinds of geometry

modules :

- Modules

that only have one object input and one object output. These could be

classified as 'neutral' and do not create any object to be added to the

object collection the TaPD object is made of. They can modify an object

(Distort module) or simply

influence the way the procedure works (Random

module).

- Modules

that have two object input ports and one object output port. These

modules decorate an object with copies of another object which is

called the decorator object. A typical example of a decorator module is

the Coil module, which is the module that is described below.

3.2.1 Coil

module

The coil module

is the current keystone of the geometry modules. It is by far the

most complicated module that can be used in a procedure. Its function

is to place and orientate decorator objects along an object to

decorate. The decoration process takes place along the vertical axis of

the decorated object much like a spiral staircase. At each step of the

"stair", a decorator object may be placed along the decorated object

depending on a probability check. Depending on parameters used in the

coil module, the decorated object can be distorted during the process.

The decorated object may also be distorted due to "counter reaction"

effects which are also setup in the module.

The use of the coil module is typically to decorate a trunk with

branches or decorate branches with smaller branches or leaves.

There is also a special mode that uses the golden ratio to place the

decorator object. In this mode, decorators positions do not follow the

"spiral staircase" scheme anymore. See the special section devoted to

the use of the golden ratio decoration.

Input / Output :

The first entry port (the left port using the default I/O layout)

corresponds to the input of the object to be decorated. The second port

(on the top) corresponds to the decorator object input. The object

output port

makes it possible to plug the decorator object to other modules which

may in turn decorate the decorator object. This recursive process

allows to create fractal objects, a common feature for trees and

plants. There are three value input ports. The first one allows to

enter an Y value used for specified customized functions to compute

parameters based on the entered value (more anout that later on, it's

rather an advanced topic). The two other bottom input ports allow to

plug constant values or

(much more frequently) customised functions that will govern size

variation

of the decorator objects (both in width and height) along the Y axis of

the decorated object. All examples shown belown were obtained using a

default customised funtion plugged into both R and Y size inputs.

Finally, the Y output port makes it possible to redirect the current Y

value of the coil module into a value input port, presumably the Y

value input port of another coil module or a golden ball module.

The edit window dialog consists in two parameter panes. The first pane

concerns basic geometric parameters that work for any

decorated/decorator object type, be it AoI object or TaPD objects

(spline mesh and tube). The second pane is relevant only if the

object used as decorator (or, in the counter-reaction effect case, used

as decorated object) is a proper TaPD object or a planar spline mesh

used to model leaves. The figure below shows

the first pane of the edit window of a coil module :

First pane of the coil module edit

window

The parameters shown in this pane are explained below. The basic

process of the coil module is the following :

- Start

from a given position and orientation along the vertical axis of the

decorated object;

- Check if

a decorator object has to be placed there;

- Increment

and repeat until the top of the object is reached.

Positions along

the vertical axis are referred to as Y positions and range from 0 (the

bottom of the decorated object) to 1 (the top of the decorated object).

This coordinate is a so-called reduced coordinate : it ranges from 0 to

1 whatever the real height of the decorated object.

Orientations of the decorator objects whithin the radial plane

(cross-sectional plane) of the decorated object are referred to as R

positions. They are usually expressed in degrees, sometimes as 2PI/n,

where n is an integer.

Incrementing both Y and R values step after step and placing decorator

objects yields the staircase (or screw) geometry created by the coil

module.

Spiral / Rings : Spiral means that

at each R step, the Y value of the decorator position is increased. A

spiral staircase layout is then obtained. Rings mean that Y positions

are incremented only after the R position of the decorator object has

gone one full turn. In that case, rings of decorator object along the

vertical axis of the decorated object are obtained.

Probability : This float number

between 0 and 1 is the probability that a decorator object is placed at

each possible position. A value of 0 means that no decorator object is

ever placed on the decorated object, a value of 1 (100%) means that all

possible positions are occupied.

Y Value button : Clicking this

button brings an editor window which is a customized function editor

taken from the procedural texture editor. This function is used to vary

the probability value along the Y axis of the decorated object. The

probability value at some Y position of the decorated object is

evaluated as :

overall value

= constant probability value x function

value (Y)

Y ranges from 0 (bottom) to 1 (top).

Supposing you want more decorators at the top of the object than at the

bottom, you could use a customized function that starts at 0.5 (for

example) and reaches 1 for x=1. Every parameter that shows an Y Value

button near the text entry can be varied along the Y axis the same way.

Use Y input checkbox : This option

is used to determine whether the Y value considered for evaluation of

the customised function value as described in the Y Value button section is internal

or external. Usually, you would use the internal Y value of the module,

i.e. the current height along the Y axis of the decorated object, to

vary the probability (or some other parameter that uses the Y Value mechanism). There are some

times, however, when you want to use a value that is input in the Y

input port. Let us suppose that you want to design a flower that is

made of a primary stem, secondary stems that decorate the main stem

through use of a coil module named coil#1, and flowers on top of the

secondary stems. The petals the flowers consist of are places using a

coil#2 module. Let us also suppose that you want the petals of the

flower to 'close' as the secondary stems are placed towards the top of

the main stem. Using the usual internal Y value to vary the vertical

angle won't help, since petals are always put at the top (1.0) of the

secondary stems. But if you plug the Y output value port of the coil#1

module into the Y input value port of the coil#2 module and activate

the Use Y input checkbox option for the

vertical angle customised function, then you can vary the vertical

angle parameter as needed.

Damping factor : Experimental

parameter that will remain in the TaPD if its proven useful. The

problem of random occupation of the decorator positions is that you

could get three decorator objects in a row and then nothing for the ten

subsequent positions. The damping factor (an integer d ) tries to attenuate this effect

by lowering the probability right after a decorator has been

successfully placed. The new probability is then probability /d , the next step it

is evaluated as probability /(d-1) and so forth for

each unsuccessfull step until it reaches its usual value. The primary

use of the damping factor is to fine tune decoration. Quite logically,

the density of decorators decreases as the damping factor increases. If

you end up with a high damping factor, it is likely that the geometric

parameters used should be modified.

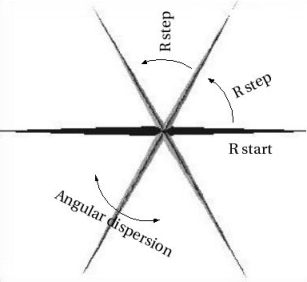

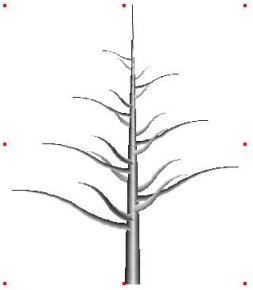

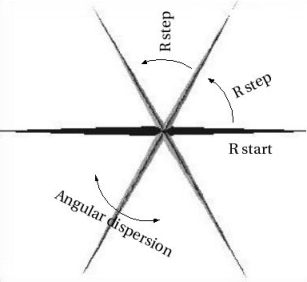

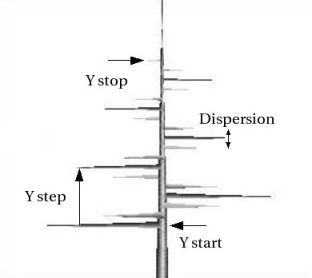

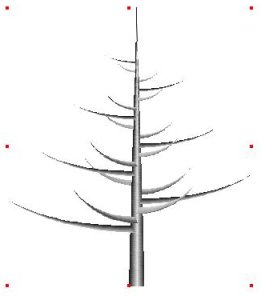

R start : this integer parameter

represents the radial angular origin at which the decoration process

begins (see figure coil.1a). It is expressed as 2PI/n, n=0 having

a special meaning : the origin is then 0. Usually, this parameter does

not need to be modified, except when two coil modules are merged. In

that case, it is customary to use a non zero integer for n so that the

two

coil modules do not place decorator objects at the same radial angular

position. You may also use the same radial origin but different Y start

parameters (see further description of this parameter) to avoid

overlapping of decorator objects.

R step : this integer parameter

represents the radial angular step separating each possible positions

of the decorator objects (see figure coil.1a below). Once again, it is

expressed as 2PI/n.

Golden ratio : if this option is

enabled, the decoration process uses a special golden section rule. See

end of module description.

Flip children : If you use leaves

that show an 'up' side and a 'down' side (different front and back

texture, or leaf distorsion) for horizontal branch decoration, the

default decoration process is such that leaves placed at R=PI/4 or

45° will show their up side globally facing towards the sky whereas

the leaves placed at R=3PI/2 or 270° will have their up sides

facing towards the ground. Activating this option causes every

decorator placed at 180<R<=360° to be flipped to keep correct

orientation. There is no mechanism (yet) to globally reorientate leaves

towards the sky once the plant or tree is build.

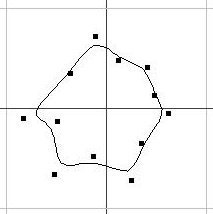

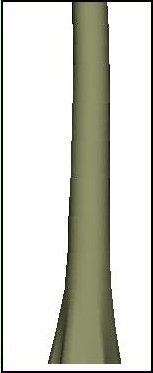

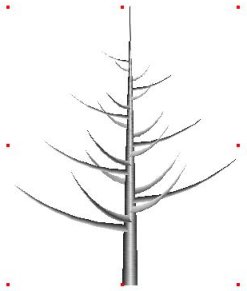

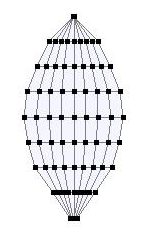

figure coil.1.a

|

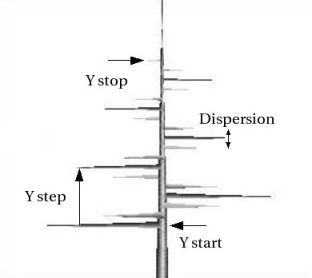

figure coil.1.b

|

Y start : this value is the Y

position where the decoration process begins. It is expressed in reduce

coordinates, from 0 (bottom) to 1

(top). See figure coil.1.b.

Y stop : this value is the Y

position where the decoration process ends. See figure coil.1.b.

Y step : the increment in Y after

each turn in R. This value can be varied along the Y axis using the Y value button.

+- : If a decorator object is

successfully placed at a given position, the Y coordinate can be

randomised by an amount corresponding to a random distribution

comprised between +value and -value. The random distribution can be

uniform or gaussian. Uniform distributions are used to randomise the

decoration process so that it does not lead to a "too geometrically

perfect" object. The gaussian distribution purpose is different : let's

suppose you are modeling a plant which places its leaves every 2PI/4

(90°) in R along the stem. Most certainly, the leaves aren't

exactly places every 2PI/4. There will be some deviation, even some

accidents for a few leaves for which the angle might get to 80° or

100°. Using the uniform random distribution do not make it possible

to reproduce that behaviour : all angular positions will be uniformly

scattered whithin the width of the distribution. The gaussian

distribution, however, yields angular values close to the perfect one,

but for a few positions that will show anomal deviation. Therefore, a

rule of thumb for choosing between uniform or gaussian is :

- if you

want to randomise decorator positions to "hide" the coil module

parameters used, use a uniform distribution.

- if

you model a plant that has well defined geometric parameters, use the

gaussian distribution to simulate natural imperfections.

Vertical angle : This parameter

represents the angle between the vertical axis of the decorated object

and the vertical axis of the decorator object. 90° corresponds to a

right angle between the two objects. This parameter can be varied along

the height of the decorated object using the Y value button. The value of the

angle can be randomised by a certain amount, entered in the +- text entry, and using a uniform

or gaussian distribution as explained before.

Horizontal angle : This parameter is

strictly equivalent to the R angular position, so in fact it's

redundant and will probably be removed. Keep the default null value.

The +- text entry, however, is important

since it allows to randomise the angular positions. For example,

looking at figure coil.1.a, it's obvious that these angular positions

do not fit for modeling a tree. In fact, angular positions should be

randomised by a uniform distribution having a width of 2PI/6 = 60°,

so a value of +-30° is sensible. Using lower values for the

distribution width can avoid having angular positions being too close

to each other, so a value of 20°, for example, might be preferred.

R shift : By default, the coil module places the decorator

objects right along the Y axis of the decorated object. If the

decorator object is small, it might not even show through the decorated

object ! The R shift parameter allows to shift radially the decorator,

so that its base lies at the surface of the decorated object. For a

TaPD decorated object, this value should be about half the R size of

the decorator (difference between a radius (R shift) and a diameter

(object module R size)). The customised function accessed through the Y value button should reproduce the

shape of the decorated object. The R Shift algorithm takes care of

radial resizings of children that might have occured in previous coil

modules. This parameter is typically useful for decorating an object

with needles. Warning : If the R shift parameter is used for objects

having a small radius (say 0.05), the preview windows might show a gap

between decorated object / decorator objects. This is not a bug in the

TaPD : it's just the precision of the preview window that is too low.

There is nothing to worry about, but the necessary precision for

rendering must be specified if theis phenomenon happens also in

rendered images.

Relative size dispersion : The size

variation along the Y axis of the decorated object is taken from the

value inputs. However, it can assumed that the sizes of the decorator

objects have

to vary randomly as well. The relative size dispersion parameter states

by which amount the randomisation affects the sizes of the decorators.

A value of 0.1 (10%) means that the size will vary between 90% and 110%

of the original object to which the size input values have been applied.

Size children : This option is quite important. Let's consider a

coil module, the function of which is to decorate branches (placed by a

former coil module around a trunk) with other branches. We will suppose

that these branches have been scaled by the first module along the Y

axis of the trunk. The second coil module must take into account the

size of each branch it is decorating and use big or small branches

depending on the size of the branch it is decorating. In such cases,

the Size children option must

be activated. The size of the decorators placed on the decorated object

are then scaled depending on the scaling which has been precedently

applied to the decorated object. There are other cases where you

wouldn't want to activate this option. For examples, leaves always have

more or less the same size whether they grew on a big branch or a small

branch. The Size children option must then be deactivated. The two

sliders at the right of the Size

children checkbox indicate by which amount the children should

resized (R size and Y size). None

means that no resizing occurs (exactly like if the Size children option was

deactivated), Full means that

the children are fully resized according to the size of their parents.

You usually would use the Full

setting for trees.

Decoration density variation with size : Still considering

the example used for discussing the Size

children option, sizing decorators causes another problem.

Presumably, small branches bear few branches than do big branches at

the bottom of the trunk. Since the coil module parameters are expressed

in reduced coordinates, the number of branches that decorate the

branches around the trunk is constant, whatever the size of the

decorated branch. This means that the density

(number of decorators per unit length) increases as the size of the

decorated branch decreases. What we want in that case is a constant

density, with a number of decorator branches decreasing as the size of

the decorated branch decreases. The slider allows to use a combination

of these two extreme cases. The constant density is the most widely

used setting, but there are certain plants that need the constant

number setting.

Important

Note : The Relative size

dispersion and Size children

must not be used on live

duplicates (Deliver duplicates

option in object modules), since live duplicates cannot be sized. This

also means that a customised function plugged into at least on the

value input ports cannot be used

on live duplicates. If this rule is not followed, the duplicate

generally end up having a close to null size due to successive

resizings. Weird things can happen like previews showing nothing.

Checking for any resizing parameter and correcting as needed puts the

procedure back in order.

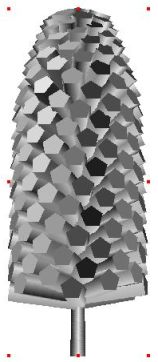

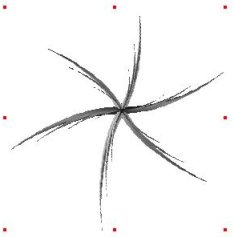

Golden ratio special case : If you use the

golden ratio, the R step value becomes meaningless since the process

increments radial positions by the golden ratio. The R origin is also

not used in that case, and both text entries are disabled. The Y step now becomes the step between two objects,

rather than the step between each turn. To calculate a relevant Y step value, the rule of

thumb is to divide the former value by the number of objects you want

along a full turn. For example, let us suppose you start from a Y step

of 0.1. If you wish to have 20 objects per turn, you would enter a Y

step value of 0.005. The use of the golden ratio rule implies that an

object is placed at every geometric position, so the probability of

having an object at a given position is always 1. All other parameters

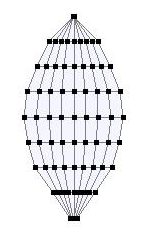

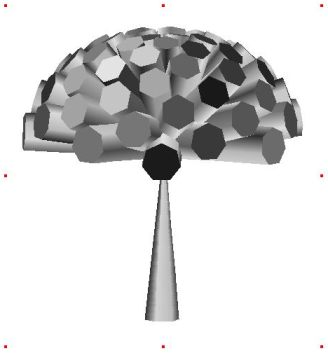

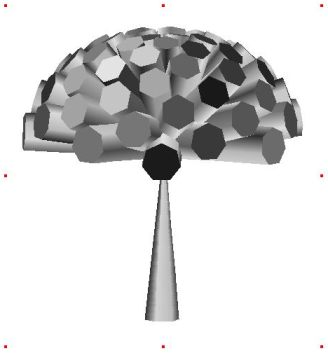

work as usual. The following figure illustrates a result obtained using

thick tubes as decorator, but it gives an idea of what could be

possible using flowers instead.

Object obtained using the golden ratio

option of the coil module

The second pane concerns

object distortion during the decoration

process. These distortions can only occur if :

- The decorator object is a TaPD object (tube or spline mesh)

- The decorator object is a planar spline mesh (leaf

distortion)

- The decorated object is a TaPD object (branching effects)

The figure

below shows the second pane.

Second pane of the coil module edit

window

The first series of

parameters address branch or leaf curving and bending. The case of

leaves is a bit special, so we'll ignore that one for now. As you have

seen from figure Coil.1, branches used to decorate a trunk remain

straight, which is most unlikely to happen in the case of real trees.

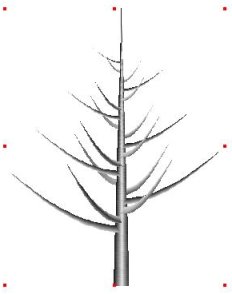

The Y

curvature angle is the angle towards which the branch tends, or

to be more precise the angle by which the branch will deviate from its

original orientation. If the vertical angle is 90° (as in figure

Coil.1), using a Y curvature angle of 40° yields figure Coil.2.a,

where the branches make a final vertical angle of 90°-40° =

50°. The default setting is such that branches follow a circle

towards final orientation. This corresponds to a curvature rate

of 1. For some trees, however, branches are curved at the bottom and

then keep straight. A curvature rate greater than one simulate this

effect. A faster curvature is imposed at the bottom of the branch,

stopping when the specified

orientation is reached. Afterwards, the branch follows a straight line.

Figure coil.2.b illustrates this process using a Curvature rate of 2. Using rates

lower than 1, the opposite effect can be obtained : branches remain

straight near the trunk and then curve near the end to reach the

specified angular orientation. If you use low rates, it is likely that

the specified orientation is never reached simply because the process

slowed down too much. In that case, you can enter bigger values for the

curvature angle in order to reach the wished orientation.

As usual now, the +- parameter

allows to randomise the curvature angle, and the Y value button allows to vary the Y

curvature parameter along the Y axis of the decorated object. The

random distribution width is also sized using this function.

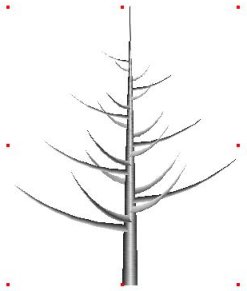

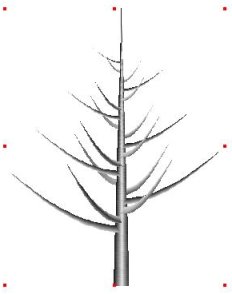

figure coil.2.a

Y curvature 40°, default curvature rate (1.0)

|

figure coil.2.b

Y curvature 40°,

curvature rate 2.0

|

figure coil.2.c

Y curvature 40°,

curvature rate 0.5

|

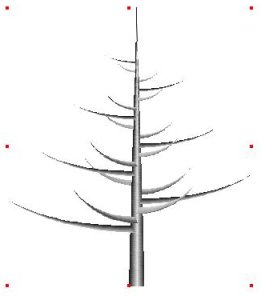

The Curve back to parameter

complicates the rules of the game evene more : it makes it possible to

get S shaped branches. When this parameter is non null, the Y curvature is applied to the first

half of the branch, twice the usual rate so that the orientation is

reached at the middle. At this point, the Curve back parameter is taken into

account, bending the branch the other way if this parameter is the

opposite sign of the Y curvature.

This design is illustrated in figure coil.3. However, you can use a Curve back parameter which has the

same sign as the Y curvature to design a special uniform shape of a

branch, if you wish to do so.

figure coil.3

Y curvature 40°,

Curve back to -40°

The

parameters of the R Curvature

work exactly the same way, except that the rotation axis is parallel to

the Y axis of the decorated object rather than perpendicular to it (see

figure Coil.4). This set of parameters are generally not of great use

to model trees. In plane motion of the branches is usually governed by

branching effects and random distorsion, see below. The Y value button scales all parameters

of this section (curvature angle, back curvature and random

distribution), except curvature rate.

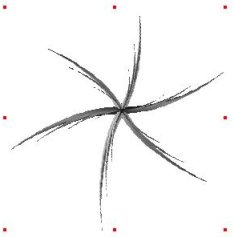

figure coil.4

R curvature 40°,

seen from the top

Branching effects : When a big

branch departs from a trunk or a branch, it often happens that the

bearer deviates from its orientation, presumably due to a counter

reaction mechanical effect. The bearer usually recover the previous

orientation after a while. The angular tilt specifies by which angular

amount "plugging" a decorator object should deviate the decorated

object. The recover rate specifies at which rate the decorated object

should recover from the branching. It is usually a high rate, from 2 to

4 or 5. Presumably, branching effects decreases as the decorator

objects get smaller towards the top of the decorated object. For this

reason, the Y value customised

function default value starts at 1 at the bottom of the decorated

object to end at 0. The figure coil.5 illustrates a branching effect

obtained by plugging a single branch into a trunk. It also show that

these parameters can be used to simulate trunk fork, which is not

possible otherwise in the TaPD at the moment.

Branching effects only work if the decorated object is a TaPD object.

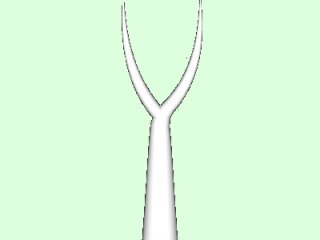

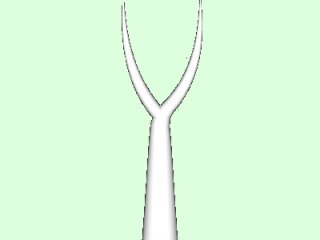

figure coil.5

Using branching effects to simulate a trunk fork

Random distortion : This parameter

works a bit like branching effects. What happens is that the shape of

some branches are like a lot of branching effects did occur, though no

branches are "plugged" at the point where the branch is distorted.

Maybe these branches fell, were cut or whatever. The random distortion

process starts to choose a random orientation and distorts the branch

accordingly. It then curve back the branch to its original orientation,

like the Curve back parameter

would do. The length of the branch affected is equal to the total

length divided by the number of random tilts to apply. The process is

repeated to the following segments using a new random orientation each

time. The Random tilt max angle

is the maximum angular amplitude that a random distortion can reach,

and the number of random tilts specifies how many segments of the

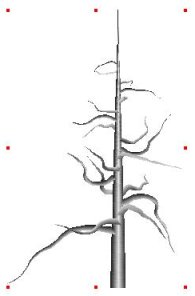

branch should be affected. The result is shown in figure Coil.4. You

can use this parameters for aquatic plants or evil-looking, gnarled

trees.

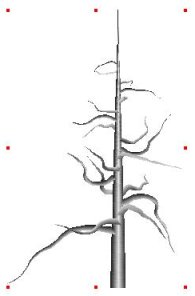

figure coil.6

Random distorsion using a max angle of 20° and 3 tilts

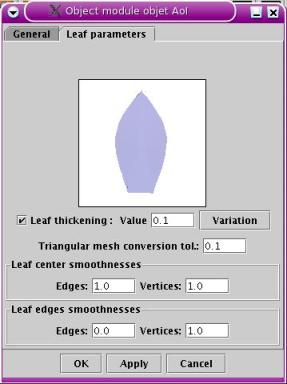

Cross-section effects : This section

is devoted to axial distortion of decorator objects. They can be

applied only if the object is a TAPD spline mesh object (the

cross-sections of tubes are circular by nature and cannot be

distorted). The first parameter, Cross-section

jitter, is the amount by which cross-section curves control

points are randomised along the radius. A value of 0.1, for example,

means that control-points will be placed anywhere between 90% and 110%

of their original radial length (taken from the center of the local

coordinate system of the curve to the control point). The result will

depend on how close in Y the cross-sections are (too close

cross-sections probably cancels out cross-section jitter) and the UV

smoothness of the spline mesh.

The twist parameters are used

to rotate cross-sections using the axis perpendicular to the

cross-section planes (Y axis). The first parameter specifies the

overall number of turns to impose to the object, and the second one is

the amount by which it should be randomised. Both parameters are float

numbers and need not be integers. Twisting cross-sections and using

random distorsion described just above on a spline mesh object with

almost flat cross-sections, the following "aquatic plant like" object

was obtained :

figure coil.7

Using cross-section twist

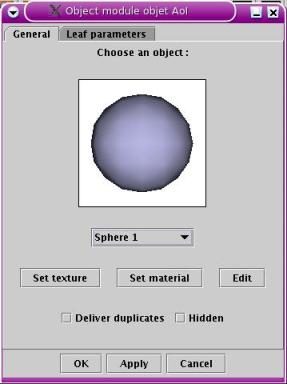

Leaves special

section :

The coil module can also distort planar AoI spline meshes to obtain

leaf distortion effects. The mesh must be created in AoI facing the

left direction (figure

Coil.8.a) for plants (leaves put on an a vertical stem) or the front direction for trees (leaves

put on horizontal branches or stems that departs from the main stem for

a plant ). After edition and shaping, an example of leaf

shape is shown on figure Coil.8.b. It is also possible to generate a

volumic triangular mesh out of this spline mesh using parameters in the

AoI object module edit window.

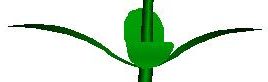

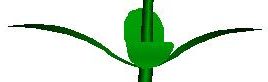

figure coil.8.a

|

figure coil.8.b

|

If this object

is imported into the TaPD and the corresponding AoI object is plugged

into a coil module, the parameters belonging to the second parameter

pane, distortion parameters,

are used to distort the leaf :

|

The Y curvature

parameter works as usual and bend the V axis of the leaf. The example

shown left results from a Y curvature of 40 and a back angle of -40.

|

|

The R curvature

parameter bends the U splines of the leaf. The example

shown left results from a R curvature of 40 and a back angle of -40

using normalised curvature. If

a random distribution is used, its component is calculated at each V

coordinate rather than once for the whole leaf.

|

|

The Random twist

parameter twists the leaf plane through rotations of the plane around

the V direction. The result for a maximum angle of 20° and a number

of twists of 3 is shown left.

|

Leaf

distortion has also a special section at the bottom of the pane to

specify special parameters that can't be expressed through use of the

parameters previously discussed.

The Leaf curvature angle

represents the in-plane distortion of the V or Y axis of the leaf. It

works exactly like other curvature angles discussed previously. The Y value function scales of the

curvature parameters. The figure below illustrates the leaf shpae

obtained with a leaf curvature of 30° and a back curvature of

-30° :

Leaf distortion

obtained with a leaf curvature of 30° and a back curvature of

-30°

The Angle at center

parameter specifies the angle that makes a leaf about its V or Y axis.

This gives the leaf a V shape as illustrates the figures below :

Leaf distortion

obtained with an angle at center of 40°

The R curvature factor modifies the way

the R curvature is applied to the leaf. Basically, there are two

possibilities :

- The leaf

shape is constant across its length and varies along different widths,

like if it is was rolled around a tube. The small sections at the

beginning and the end of the leaf show small curvature, if not flat.

This scheme is called constant curvature.

- The

curvature is constant across the width of the leaf and vary along the

length. The small sections show the same shape as the main section of

the leaf, only scaled down. This scheme is called normalised curvature,

because it is normalised for each width of the leaf across its

length.

The R curvature factor slider allows to

choose any value between these two extremes. The figures below show

three leaves modeled using a R curvature angle of 70° in order to

exaggerate effects. The figure on the left uses a constant curvature

scheme. It looks much like a part of a tube surface, except for camera

distortion effects. The figure on the

right uses normalised curvature. With such a high

curvature angle, the spline mesh closes on itself like two parts of a

sea shell.

Three R curvature

values : constant curvature (left), normalised curvature (right) or

halway between the two (middle).

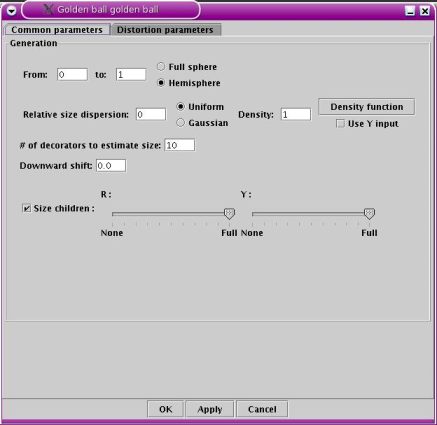

3.2.2 Golden

ball

module

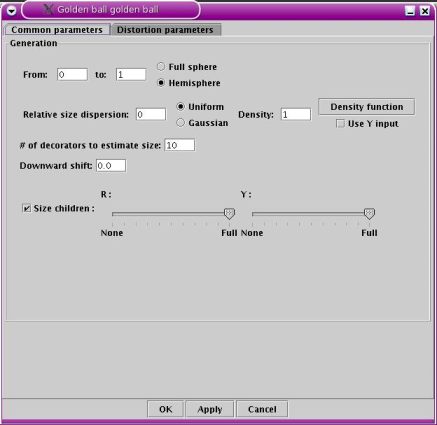

The golden ball

module paces object along the radii of a sphere following the golden

ratio rule. Its input and output ports are exactly the same as those of

the coil module. The figure below whows the golden ball edit window :

Golden ball module

edit window

The Sphere and Hemisphere radio buttons specify if

the decoration geometry concerns a whole sphere or only half of it.

The from and to parameters specifies which part

of the sphere (or the hemisphere) should be considered. The process

starts from the top of the sphere at a coordinate of 0 ad ends at the

bottom for a coordinate of 1 for a sphere. The same considerations

apply to an hemisphere, except that the bottom is the disc section of

the half sphere. For example, using from and to values of 0.25 and 0.75

for a sphere means that the decoration process will happen in the

middle of it. A full hemispherical decoration is equivalent to using a

spherical decoration ranging from 0 to 0.5.

The Relative size dispersion

works exactly like in the coil module.

The Density parameter

represents how dense the packing of decorators is. The golden ball

module first calculate a density based on the R section of the

decorators, taking also into account any decoration process they might

have gone through. If this density is too small or too big (usually it

is to small for a close packing), you can increase/decrease it using

the density parameter.

The Density function button allows to

edit the customised function that specifies how density should vary

from the from parameter to the

to parameter. It is thus

possible to have a close packing at the start of the decoration process

and a loose packing at the end. The overall density used is the density

parameter multiplied by the value of the customised function at a given

point between from (origin of

the customised function) and to

(abscissae of one). Due to mathematical considerations, it is not

possible to ensure that an overall density that starts at 1 and ends at

2 gives the same result at the start than a decoration with a constant

density of 1 and at the end than a decoration

with a constant density of 2. Thus, It is likely that the density

parameter must be tuned to reach the wished result when using the

density function. The density function could be used to densify packing

when decorators get smaller due to the use of a size customised

function, for example.

Use Y input checkbox : As for the

coil module, this option makes it possible to use a value input in the

Y input port. The density is then constant (except when a random value

is input in the Y input port) and equal to the product of the density

parameter times customised function value calculated at the input value

coordinate.

The # of decorators to estimate

specifies how many decorators should be evaluated to estimate the

packing density. You can decrease this number if decorators have more

or less all the same size or increase it if the size varies a lot from

one decorator to the other.

Downward shift : by default, the

generated object is placed at the top of the decorated object. The downward shift allows to place it

anywhere along the height of the decorated object from the top

(downward shift = 0) to the bottom (downward shift = 1).

The Size children settings works exactly like in

the coil module.

The second pane allows for

distortion of the decorators object following the principles explained

in the coil module section.

Important

note : if the decorators show a very small section (very thin

tubes, for example), the density calculated by the golden ball module

might generate by default a huge number of objects, presumably causing

long computation time, if not an Out of Memory error. If you use

decorators with a tiny section, start with a low density

parameter, and increase as needed.

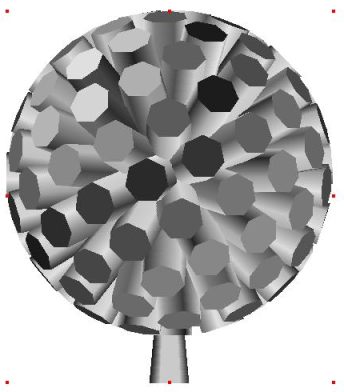

The following figure shows a result

obtained

using thick tubes as decorator :

A simple packing of

tubes

|

Hemispherical packing

of tube using a customised

size function plugged into the size inputs of the module

|

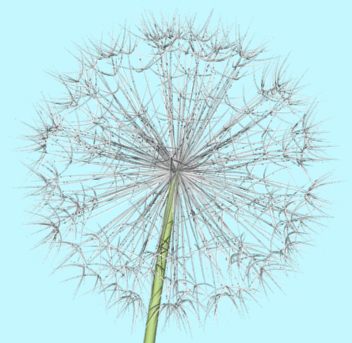

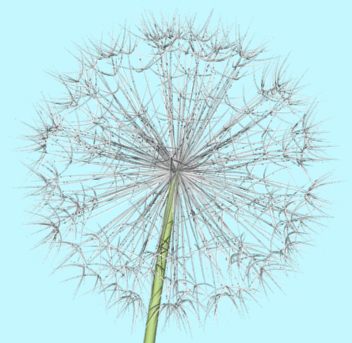

The dandelion flower shown below has been modeled using the golden ball

module. It is available in the example files. The dandelion flower

example and the principles of using the golden ratio to create a

spherical object is described in references [2] and [3].

A dandelion flower

modeled using the golden ball module

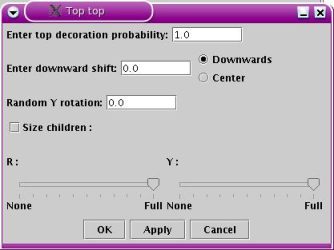

3.2.3 Top

module

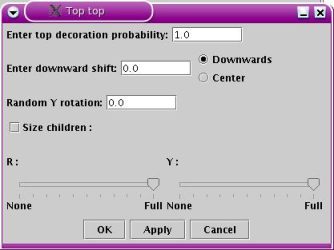

The top module

makes it possible to place the decorator object on top of the decorated

object. It is a simple geometry module. The edit window is shown below :

Top module edit window

The top decoration probability

is the probability that a decorator object gets placed on top of the

decorated object. The downward shift is the downwards translation

applied the decorator in reduced height of the decorated object. A

value of 0.05, for example, means that the decorator will be placed at

95% of the height of the decorated object. Using this parameter it is

possible to have a small overlap between the decorated object and the

decorator. Radio buttons allow to choose between Downwards, which the design which

has just been discussed, and Center.

If the Center radio button,

the decorator and decorated object centers are superimposed. For

example, this allows to place a light whithin a sphere. The Downward shift is ignored if the Center option is used.

The Random Y rotation allows

to rotate randomly the decorator object around the Y axis by a maximum

+- the value entered (in degrees). Using this parameter, it is possible

to avoid that flowers put on top of stems have all the same orientation

with respect to the Y axis.

The Size children function

works as for the coil module, see above.

3.2.4

Distort

module

Using the coil

module, it is possible to distort the decorator objects given a set of

parameters. However, it is not possible to distort the decorated

object, except considering branching effects. The distort module makes

it possible to distort the decorated object as well. The edit window is

not shown here, it is a replica of the second pane of the coil module

edit window minus the branching effects parameters. The main use of the

Distort module is to distort a

starting object (say a trunk) before plugging it into a decoration

module. It can also be used to distort an object before plugging it as

decorator in a top module.

You should not plug the Distort module output into the

decorator input of a coil module. The distortion parameters of the coil

module will cancel any previous distortion carried out by the distort

module.

3.2.5 Random

module

If an object

port output has multiple links, all the decoration processes

resulting from these links will be merged. Sometimes, however, it is

wished that one of these links should be chosen at random rather than

to have all the links results merged into a single decoration (these

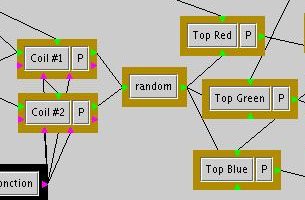

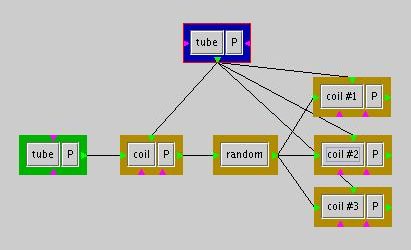

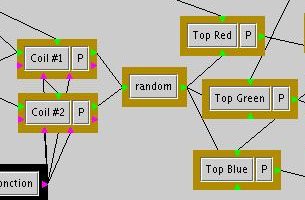

considerations are discussed at length in the next chapter). The figure

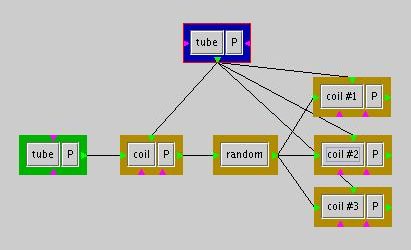

below illustrates a typical use of the Random

module :

Random module example

Whithout the random module inserted between the first coil module and

the other coil modules named #1 to #3, the three decorations

carried out by the three coil modules would be merged for each

decorator of the first coil module. Using the random module, however,

one of the #1, #2, #3 coil module is chosen for decorating each

decorator of the first coil module.

It is also possible to specify the probability of following a specified

output link. Let's consider the following example, taken from the lamp example file :

Random module used in

the lamp example

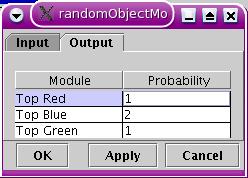

The default parameters of the random module are such that the

probabilities of decoration with a red, blue or green light are all

equal. Clicking the edit button brings this edit window :

Random module edit

window

The tabbed pane consist in two tables, the input probabilities table

and the probabilities table. We will focus on the latter and suppose we

want twice as much blue lights than any other colour. Entering the

probabilities shown on the screenshot leads to such a situation. The

probabilities need not be integers or floats normalized to one, you can

use any scheme you wish (i.e. 0.25, 0.5, 0.25 or 1, 2, 1).

The other pane is devoted to input probabilities. This situation occur

if, for example, you plug three object modules into the input of a

random module and the output of the random module to the decorator

input port of a coil module. If you do not use the random module, the

default scheme is to choose as decorator one of the three objects at

random. If you use the random module, however, you will be able to

specify different probabilities for each one of the three objects.

The random process works either for the input port of the random module

or for its output port, depending on whether it is placed upstream

(random input) or downstream (random output). For upstream and

downstream definitions, see chapter 4.

Due to its function, the random module does not have a preview button.

3.3

Value modules

3.3.1

Constant value

module

The constant

value module holds a float value, exactly like the procedural editor

value module. Its use is straightforward. One interest of the constant

value module is to plug it into one of the size entries of an object

module so that the size of the object can be quickly modified whithout

having to edit the object itself each time a size fine tuning is

required.

3.3.2

Customised function

module

The customised

function module works exactly like the procedural editor customised

function (see AoI manual). Its main use is to be plugged into the coil

module size entries to vary the size of the decorator objects along the

Y axis of the decorated object. The editing window shows two additional

buttons, Copy function and Paste function that can be used to

copy and paste function control points and options between two editing

windows. These buttons can be used to replicate function definitions in

geometry modules like the coil module that makes heavy use of

customised functions.

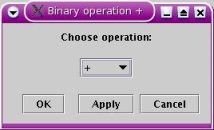

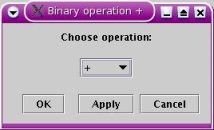

3.3.3 Binary

operation module

This module

takes two input values, named a

and b, and computes a result

r = f(a,b). The available operations not only include +, -, *, /, but

also <, >, Min, and Max. The type of operation performed is

selected in a combo box in the edit window, shown below. An illegal

operation like dividing by zero yields a zero value on output and an

error message in the console.

Binary operation edit

window

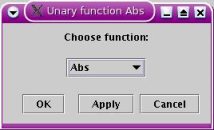

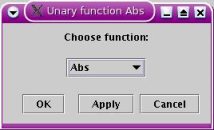

3.3.4 Unary

function module

This module

takes one input value, named a,

and computes a result r = f(a). The available operations include abs,

exp, log, square root, sine and cosine. the sine and cosine are

normailzed to PI/2, ie. f(a) = sin(a*PI/2). The considered function is

selected in a combo box in the edit window,

shown below. An illegal operation like log(<=0) or sqrt(<0)

yields a zero

value on output and an error message in the console.

Unary function edit

window3.3.5

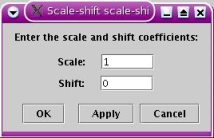

Scale/shift module

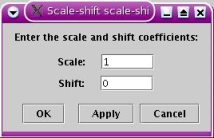

This module,

identical to the one found in the procedural texture editor, takes one

input value and applies the

following linear transformation r = scale*a +shift. These two parameters

are entered in the edit window shown below.

Scale-shift module edit

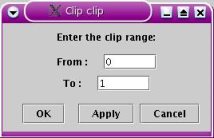

window3.3.6

Clip

module

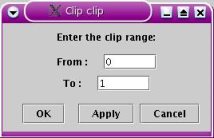

The clip module

is also identical to the one found in the procedural texture editor. It

takes one input value and applies the

following rules

a < min -> r = min

min <= a <= max -> r = a

max <= a -> r = max

The min and max parameters are entered in the

edit window shown below.

Clip module edit

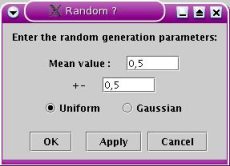

window3.3.7 Random

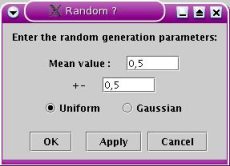

value module

The random

value module delivers a random number following a random distribution

specified by the user. These parameters are the mean value of the

distribution and its spread. As for the coil module, two kinds of

distribution can be used : a uniform distribution and a gaussian

distribution. The edit window is shown below :

Random value edit

window